BIRMINGHAM, Alabama — New guardrail technology currently undergoing federal review has the potential to save even more lives, especially in crashes near bodies of water.

10 Investigates went all the way to Alabama to see a crash test using the new technology. While there, Investigative Reporter Jennifer Titus spoke with the man who revolutionized the guardrail industry, including creating live-saving technology for NASCAR in the wake of Dale Earnhardt's death.

That same man is behind this latest progression in guardrail safety and technology.

The Next Generation Terminal

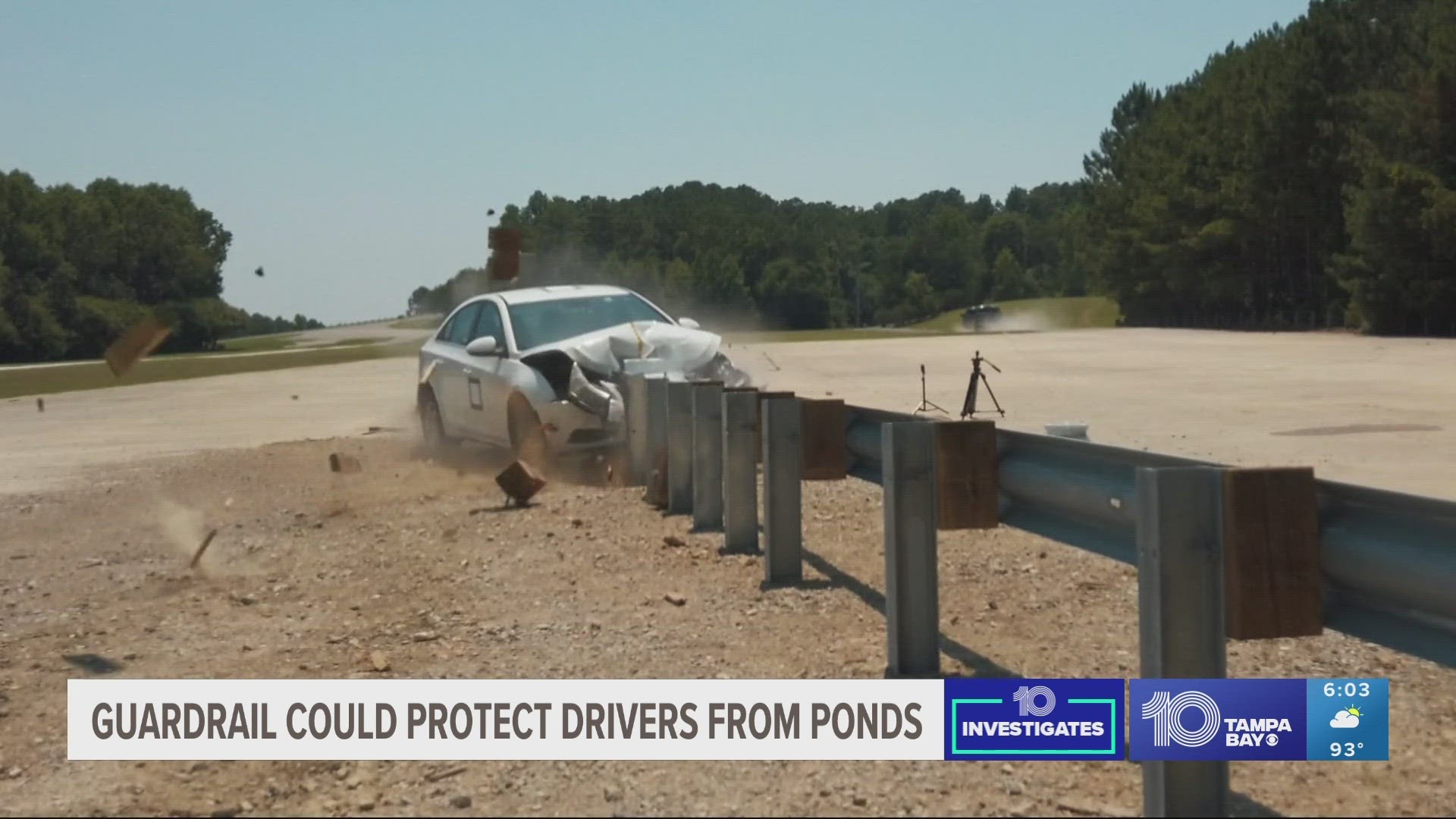

It’s a 98-degree day at a motorsports park outside of Birmingham, Alabama. Dr. Dean Sicking and Dr. Kevin Schrum have been waiting for this for 7 years. They are performing a crash test for their Next Generation Terminal.

Unlike other guardrails, this one is not designed to allow a driver to keep going past it. That could be critical in spots where drivers could potentially go off the road and into the water.

“I think it's going to revolutionize the guardrail terminal industry without a doubt. I think that within ten years there will be no more old-style terminals,” engineer and inventor Dr. Sicking said.

This isn’t the first time Dr. Sicking has worked to revolutionize the guardrail industry.

“My first experience was 1988 when we developed the compression technology, which is what was used today, still today and it didn't take long, that every highway, almost every highway agency in the country found a public interest, finding that our terminal was so much better than anything else, they would only use our terminal,” said Dr. Sicking.

After Dale Earnhardt’s death at Daytona International Speedway in 2001, Dr. Sicking developed a new safety barrier used today on NASCAR tracks.

“It was a revolutionizing of the approach to design. Until that time, we basically we had had a trial-and-error system where we would run a crash test, think about what would we fix and brainstorm and decide on some changes, and we tested it again. And during that year, you'd have 40 or 50 crashes before you got a product that worked,” said Dr. Sicking.

He was then awarded the National Medal of Technology and Innovation by President George Bush. You can see how he was recognized in this clip.

“It’s about saving lives. I mean, thousands of people out there who run into my safety hardware and are alive today because of it,” said Dr. Sicking.

It’s what brings us to the crash test in Birmingham, where Dr. Sicking now works with Dr. Schrum.

They’re awaiting federal approval for their Next Generation Terminal.

“The guardrail terminal head kind of bit into the front of the vehicle and caught it started out at ten degrees they ended up staying on the guardrail didn't even spin out to the back side,” said Dr. Schrum.

Schrum says it would prevent drivers from having incidents like this one in Minnesota. A truck hit the end of a guardrail on the interstate and traveled more than a hundred feet before rolling over the side of a barrier and onto a highway below. The driver survived.

“What we're finding is that in a lot of cases that body of water or that bridge or whatever it is is 120 feet away, 150 feet away. And yet we're still getting 250 fatal crashes per year,” said Dr. Schrum.

“We found many lives could be saved if we could solve this problem. And I, I had an idea for how we could do it and it took us a long time to go, seven years. But, we got it done and there'll be a lot of people alive next year,” said Dr. Sicking.

Chloe Arenas died in 2015 after her car crashed into an Orange County pond.

“And I kept calling her phone. There was no answer,” said BB Arenas, Chloe’s mom. She says Chloe was supposed to pick up her and her mother to go to the airport for a trip to Central America. Arenas thought perhaps her daughter just overslept. Her family says she was charitable and dependable. Chloe was studying to become a veterinarian.

“She loved working with exotic animals, elephants were one of her favorites. She just loved all kinds of animals,” Arenas said.

When Chloe’s car was pulled out of the pond, her schoolwork was scattered, even her stethoscope was on the floorboard. Chloe’s best friend saw a story posted online showing her black Hyundai Elantra.

“I remember before anybody confirming just dropping to the ground. It's like everything just kind of came out of you,” Clarissa Lindsey, Chloe’s best friend said.

Lindsey says the shock of the grief put her in fight mode. She realized there was no guardrail to stop Chloe from going into the pond at the end of an exit ramp for State Road 408.

That sparked an online petition, and eventually, Florida lawmakers passed Chloe’s Law, requiring guardrails where someone has drowned in a car crash between 2006 and 2016.

“We didn't get everything that we wanted, which is common with the first time that a bill is born,” Lindsay said.

While Chloe’s family and friends have fought to get a guardrail installed where her car veered off the road, it still hasn’t happened.

The county says it’s not safe to put one there.

Chloe’s accident happened shortly before these engineers started working on the Next Generation Terminal. The most recent crash test on June 28 was exactly eight years after Chloe’s death.

“She’s not just special within these four walls of our home, and because she's my family, and because she's my sister like she really is, as she leaves his house, she is touching people,” Lauren Duffield, Chloe’s sister said.

Chloe’s friends and family are excited about the possibilities of this new guardrail terminal.

“We need that protection, especially around these bodies of water, these ponds. They're so dangerous. It's, it's just, to me again, it's just like you said, a no-brainer. There should be one there. There should have been one there already,” Arenas said.

"I just think that there has to be a solution. There's always a solution," Lindsey said.

And these engineers think it could be a game changer when it comes to saving lives.

“They hit a guardrail. Any kind of crash. This keeps them from continuing to go from continuing. They end up in that pond, hitting that utility pole. That's what makes this different,” Dr. Schrum said.

Schrum says, unlike the guardrails we’ve shown you over the last six months that were improperly installed, this should be relatively easy to install and has very few parts that can be intermingled. It took a crew just 45 minutes to put one together.

The product is under federal review. They hope it's approved by the end of the year.